Applications Overview

Due to its unique characteristics which combine the robustness of welded overlays and the low heat input of thermal spraying laser cladding is applicable to a wide range of marine parts. Furthermore, the versatility of the technique is enormous as parts from a 22mm turbo rotor shaft to a 26 ton propeller shaft can be successfully processed by the same system by simply altering welding parameters.

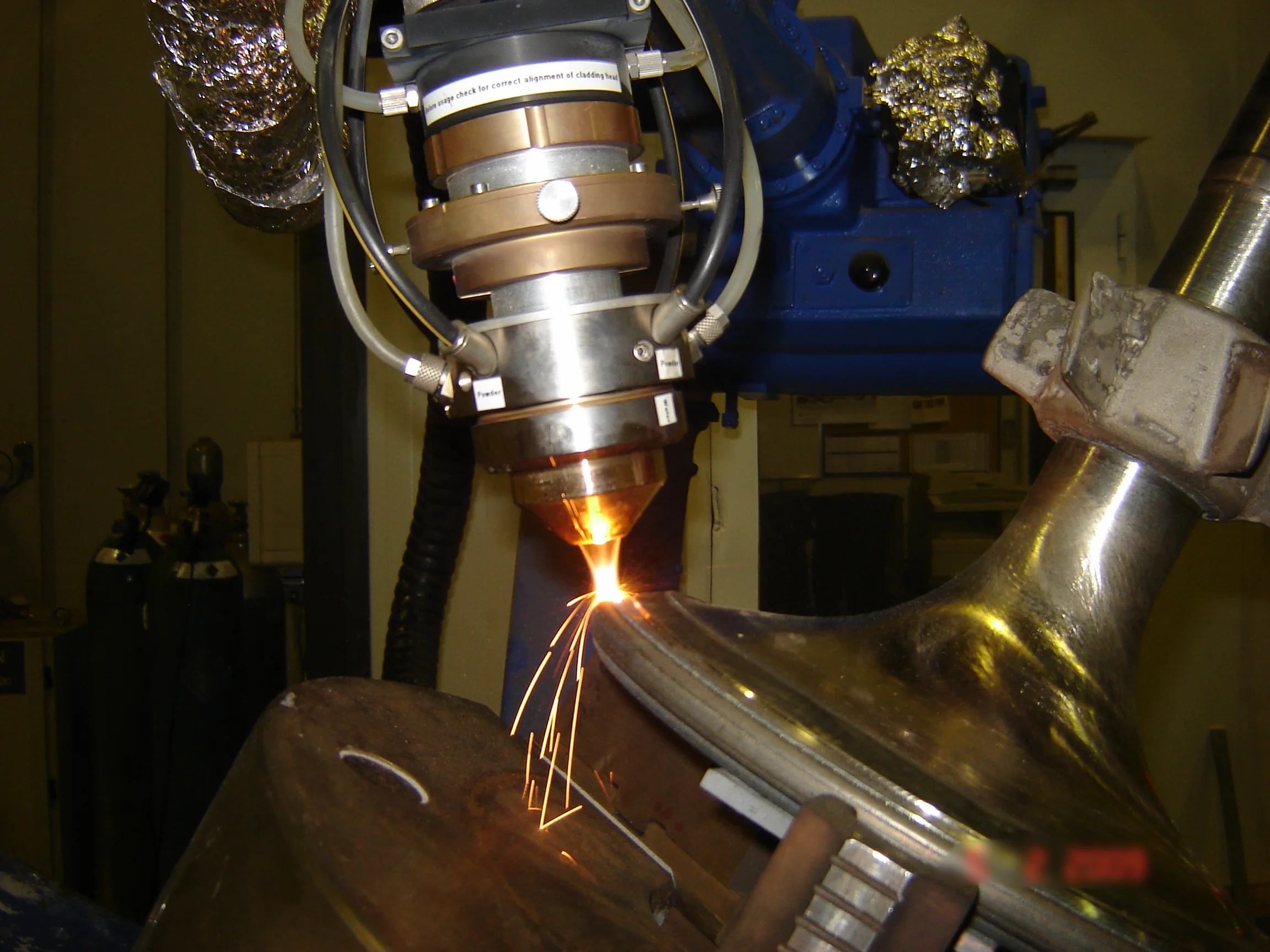

Propeller Shafts

The high quality, fully automated nature of this welding process accompanied with its distinct metallurgical advantages render it ideal for the reclamation of critical components such as propeller shafts.

Piston Rods

The fully dense, metallurgically bonded overlays and the capability of applying hardfacing materials with poor weldability have rendered laser cladding the only option for hydraulic rod applications in the marine and offshore sectors.

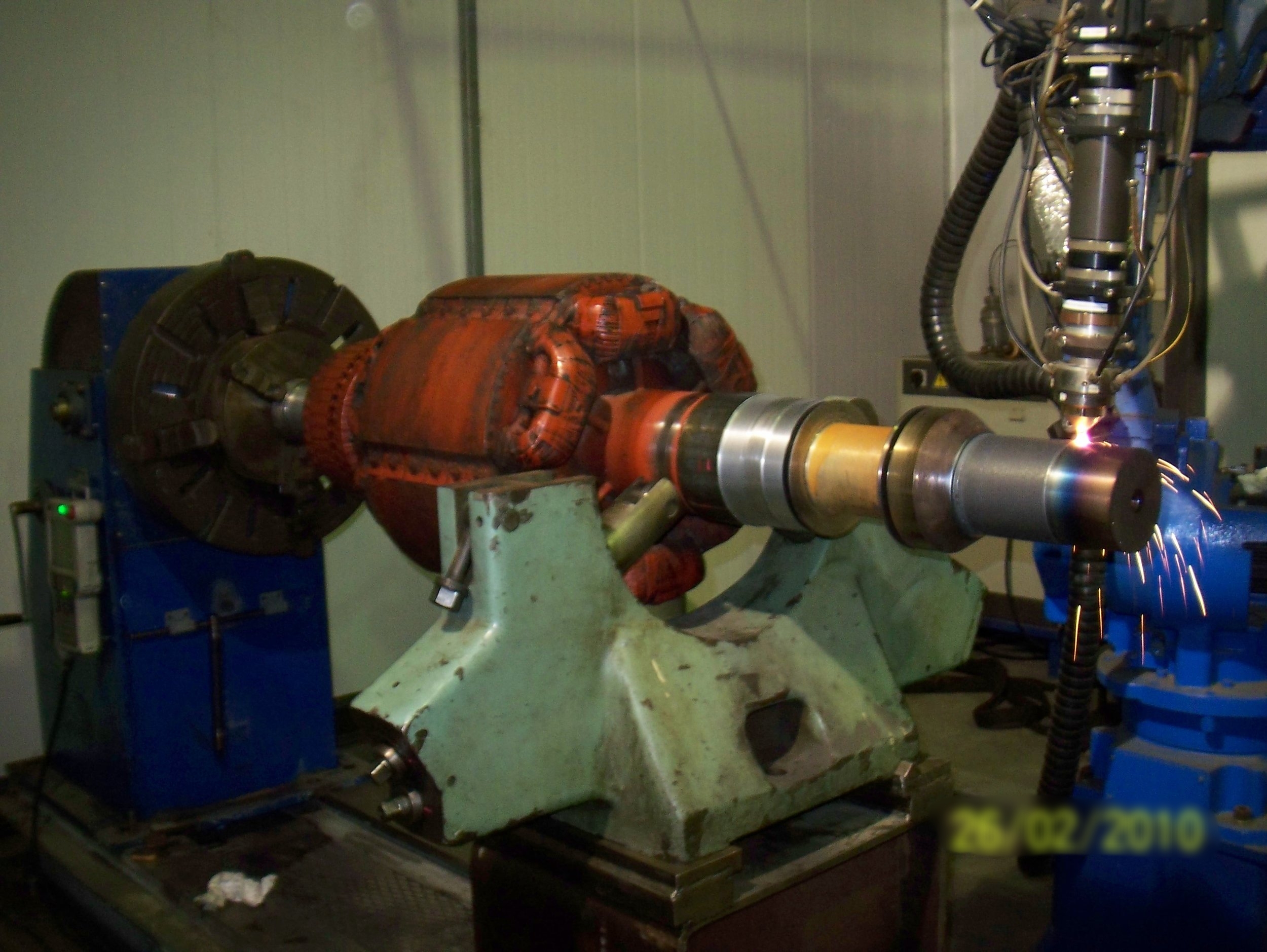

Rotors

Laser cladding results to significantly lower heat input to the work piece and minimised distortions. Rotors featuring sensitive equipment which cannot be dismantled from the shaft are ideal applications for this process.

Exhaust Valves

The finer microstructure and the excellent weld bead dimensional control provide improved results from the metallurgical and economical point of view.

Cast Iron Parts

The low heat input and low dillution levels render cast iron welding relatively trivial. Expensive and difficult to find castings can now be repaired in a cost effective manner with improved surface properties compared to the original.